Products

Scallable for Production or R&D Applications

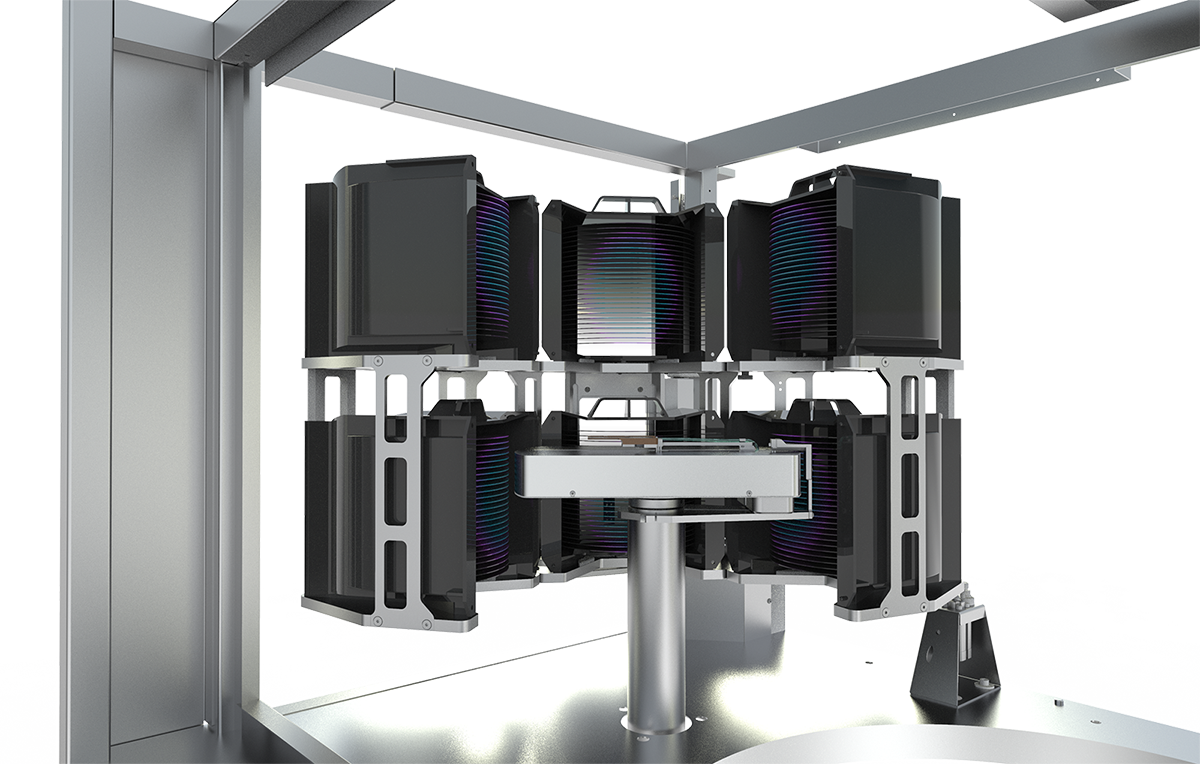

SVCS Vertical Thermal Reactor (VTR) is designed for all standard atmospheric and low pressure CVD processes. VTR is available with several lengths of flat zone for both mass production and R&D application. The single tube set-up with dual boat logistics is optimized for minimum down time as well as low maintenance costs.

Features and Benefits

- Automatic wafer handling system for loading wafers from SMIF or FOUP closed pods

- Special automatic loading system which allows loading wafers from open cassettes and provides an exceptionally small footprint

- Quartz or SiC boats can be used

- Highly tailored state of the art modular control system, in house designed and manufactured

- 10,4“ high-res touchscreen for operator interface

Atmospheric Processes

- Diffusion (drive-in) high temperature procesess

- Doping from solid, liquid and gaseous dopant sources e.g.: BBr3, B2H6, POCL3, PH3, BN

- Various thermal processing e.g. annealing, sintering

- Pyrogenic Wet Oxide with External Burning System

- Dry Oxide

LPCVD Processes

- Silicon nitride / low stress nitride

- Low temperature oxide (LTO)

- High temperature oxide (HTO)

- TEOS oxide

- Polysilicon, with tilt/flat temperature profile

- Doped polysilicon

- Oxynitride

DCE or HCl optional for all processes

Technical Data

| Wafer size (mm) | 100, 150, 200, 300 or any custom size |

| Wafer load | 25 – 150 wafers/batch |

| Heating system | 3 or 5 zones |

| Flat zone | up to 600 mm (24″) |

| Process temperature | 200 oC – 1230 oC, ± 0.5 oC across flat zone |

| Power consumption | 22kW – 30kW |

| Power supply (adapted to power grid of destination country) | 3-phase, 400 or 480VAC, 40 – 100 A, 50 or 60 Hz |

| Clean dry air | 70 – 110 psig (4,8 to 7,6 bar) |

| Cooling water | 10 – 15 LPM |

| Exhaust | 170 m³/h |

-

Singapore

Singapore

Singapore

Singapore

Sam Chan

Regional Business Network Pte Ltd

16 New Industrial Road

#04-08 Hudson Technocentre

Singapore 536204Tel: (65) 62809650

Fax: (65) 62809675

Mobile: (65) 96170912Web: www.rbnpl.com

-

Germany

Germany

Germany

Germany

European Market Partner BV

Park Reeburg 27

5261 GC Vught

The NetherlandsTel: +31 495 54 58 17

Cell: +31 6 24 759685

Email: -

Netherlands

Netherlands

Netherlands

Netherlands

European Market Partner BV

Park Reeburg 27

5261 GC Vught

The NetherlandsTel: +31 495 54 58 17

Cell: +31 6 24 759685

Email: -

France

France

France

France

Bruno MERCIER – Business Partner

Self entrepreneur

Expert in Microelectronics, MEMS and Clean room environment

Tel : + 33 6 62 47 30 42

Email:172 Rue des Bauges

74210 Doussard

FRANCE

-

Hong Kong + Taiwan

Hong Kong + Taiwan

Hong Kong + Taiwan

Hong Kong + Taiwan

Great Domain

Mark Chang

Enterprise Co., Ltd.

15-1F, No.37, Sec. 2, Sanmin Rd.,

Banqiao Dist., New Taipei City, Taiwan

Tel.: 0912-730-586

Fax: 0289538399

Email: -

Vietnam

Vietnam

Vietnam

Vietnam

AMST., CO. Ltd.

Mrs. Le Thi Thu Huong

48A, Alley 21 Phan Dinh Giot Str.

Thanh Xuan Dist., Hanoi

Vietnam

Tel: +84 2466831909Mobile: +84902245626

Email: info@amst.com.vn / sales@amst.com.vnWeb: www.amst.com.vn

-

Australia

Australia

Australia

Australia

UHP Australia Ply Ltd.

Unit 4, 20 Velediclion Road, Kings

Park NSW 2148, AUSTRALIA

Tel.: +61 (0)2 9676 6769

Mob.: +61 (0) 3904 3893

Email: -

Japan

Japan

Japan

Japan

VYTEK Ltd.

Mr. Vladimir Kovacik

Wisteria Komae bldg.3F

1-2-8 Izumi Honcho, Komae, Tokyo, 201-0003 Japan

Tel.:+81-3-3480-9082

Fax:+81-3-3480-9083

Email:

http://www.vytek.co.jp/ -

Korea

Korea

Korea

Korea

Sang-Hoon, Lee (Mr. Edward Lee)

Managing Director of SH Korea

#310-213, Ansan Distribution Complex

994-6, Wongok-dong, Danwon-gu,

Ansan-si, Gyeonggi-do, Korea.

zip code 15431

Fax: +82.31.8084.4744

web-site: www.shkorea.kr

Mobile: 82-10-4307-8412

Email: -

Taiwan

Taiwan

Taiwan

Taiwan

Sung Yuan Biotechnology Co., Ltd.

Mr. Thomas Liu

Sales Director

No.818, Wen-San Road, Up-Mountain village

Chung-Lin Hsiang, Hsin-Chu County 307,

Taiwan R.O.C

Tel: +886-3-5122.096 ext 101

Fax: +886-3-5925.308

Mobile: +886-938-365.326

Email:

Email: -

China

China

China

China

PELAS

Mr. Tony Wang

Shanghai PelaStar Materials Technology Co., Ltd

Room. 1102, Suncome Liauw’s Plaza, No. 738, Shangcheng Rd.Shanghai, 200120, China

Tel.: 86-21-51981110

Fax.: 86-21-51981109

Mobile: 13816658585

Email: -

Malaysia

Malaysia

Malaysia

Malaysia

SERMAX Engineering Pte Ltd (201025665Z)

11 Mandai Estate, #08-01 Eldix, Singapore 729908

Phone : +65-6710 7710

Fax : +65-6710 7710

Email: -

India

India

India

India

MCube Technologies Pvt Ltd.

204, Ashok Sankul II, Ashok Nagar,

Off Range Hills Road, Shivajinagar, Pune- 411007Contact: Mr Akshay Patil

Mob: +91 (0) 9763 7180 58Office: +91 (0) 2025 5606 66 (Sales)

Email:

Email:

www.mcubetechnologies.com -

Russia

Russia

Russia

Russia

OOO “SVCS”

Mr. Igor Berezenko

Director

Solnechnaya alley, bld. 6, office 223

Zelenograd, 124498 Moscow

Russia

Phone: +7 495 790 63 31

Email:

https://www.svcs.com -

Turkey

Turkey

Turkey

Turkey

TESTONE TEKNOLOJI COZUMLERI SAN. VE TIC LTD. STI.

Gürsel Mah. İkbal Sok TestOne Binası No :7

Kağıthane-İstanbul

Tel: 0212 251 24 25

Fax: 0212 222 90 90

Email: -

USA

USA

USA

USA

SVCS CO.

1819 Main Street

Sarasota • Florida 34236 • USA

www.svcs.com

Email: